Description

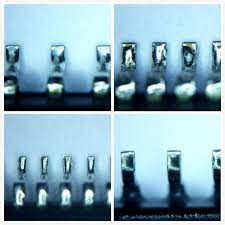

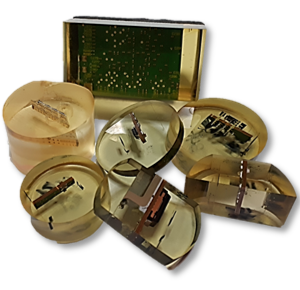

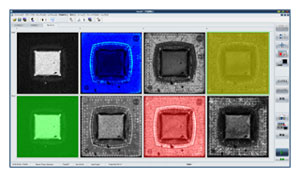

According to the test standard of the solderability test, this test mainly detects whether the soldering ability of the chip pins meets the standard. Solderability testing is generally used to make a qualitative and quantitative assessment of the solderability of components, printed circuit boards, solders and fluxes. In the assembly and welding process of electronic products, the quality of welding directly affects the quality of the whole machine. Therefore, in order to improve the welding quality, in addition to strictly controlling the process parameters, it is also necessary to conduct scientific solderability tests on the printed circuit boards and electronic components. Through the implementation of solderability testing, it helps companies determine the solderability and product quality after production and assembly. In practice, the microspectroscopy technology has further enriched the technical means of solderability testing of printed circuit boards and other components, clarified the internal factors affecting solderability, and improved product quality and zero defects for technical engineers in the manufacturing industry. The welding process has given a great help.