Description

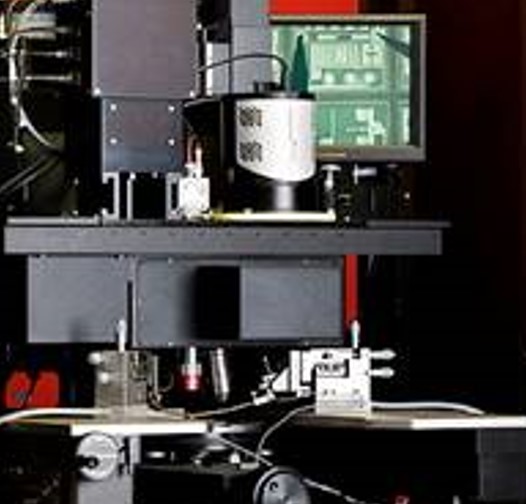

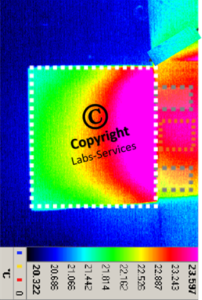

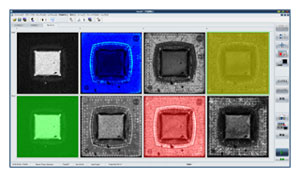

In electronics, all devices generate heat to some degree. Some heat emitted by device is normal but certain types of defects can increase power consumption, thereby increasing the amount of heat letting off. In Failure Analysis, this additional heat emitted can provide useful clues to the defect itself. Thermal Emission Microscope is an useful technique to measure visible or near-infrared light by an in-built special camera system. This camera is sensitive to photons with wavelengths of anywhere from 3 to 10 um. These wavelengths correspond to heat so that the image obtained with the camera can be converted into a thermal map of tested devices.

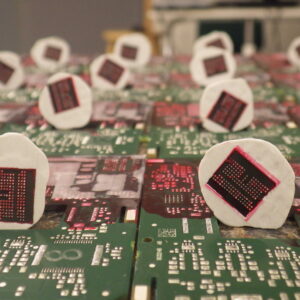

Generally, a sample device will be imaged thermally when power-off, to establish the reference line; then power-up to image again. The resulting image is a visual representation of a device’s power consumption, and can be used to isolate a failure.

Many different defects can generate excessive heat when power-up because they consume extra current. Examples like short circuits, poor transistors, damaged ESD protection diodes will show up when observed by Thermal Emission Microscope and allows us to pinpoint the defective damage site.