Introduction

The electronics industry is making a tremendous investment in surface mount technology. The reasons for this investment include cost savings resulting from automated component placement and increased density of PCB layout due to smaller package sizes. Today’s placement machines can pick and place thousands of components per hour with a very high degree of accuracy. To achieve this performance, the component delivery system must be capable of feeding parts at high speeds in a consistent orientation, positively indexed to the demands of the machine. The leads of the components must be protected from damage during shipment, handling, and placement. The preferred packing material available today for these demands is tape and reel. Tape and reel packaging is the best way to handle, process, store, and transport electronic components. It provides protection and makes precision surface-mounting of components easy. Manufacturers must follow tape and reel packaging standards. This ensures that there are no problems during the automated surface mounting of components.

Our service

We offer service of tape and reel packaging to customers within the semiconductor industry. Tape and reel packaging is a process of packaging electronic components, especially surface mount devices (SMDs) components, uses individual pockets on the carrier tape. Each pocket houses an electronic component that is then covered with heat or pressure seal cover tape. The tape containing sealed pockets of parts is then wrapped around a reel, making them easy and safe to handle and feed into automated assembly machines during manufacturing applications. It is efficient for mass production and protects components during shipping and storage. These reels are dust-free and compatible with a clean environment.

Our new generation automated taping system is specifically used for IC tape and reel packaging to deliver flexible, reliable, and quick services as per industry standards and conformance with the EIA Standard-481. EIA Standard-481 tape and reel provide manufacturers and purchasers with guidelines, which eliminates misunderstandings and improves product quality. Our tapping system supports devices packaged in 8 to 88mm width tape, 32 mm depth carrier tape and supports JEDEC standard tray, and up to 22” (550mm) input tape reel, which is equipped with different sensors to ensure packaging quality and prevent human or system errors.

Our commitment

With advanced characteristics, our machine offers the best solution for manufacturing process to provides your product with the quality you demand and deserve. In every tape and reel packaging service, our team carefully chooses tape and reel materials to prevent loading/unloading issues and electrostatic discharge (ESD) failures in sensitive electronic parts.

Baking Service

We also provide the Temperature regulated baking of the electronic components as value added service following JEDEC standard.

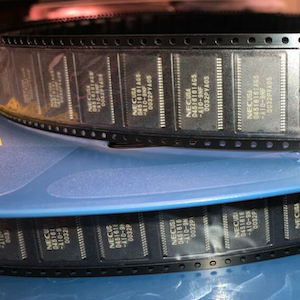

Fig 1: Automated Tape & Reel machine

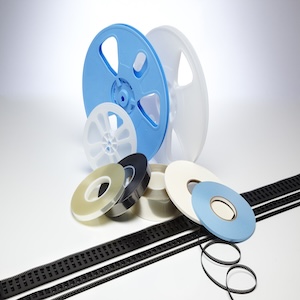

Fig 2: Tape & Reel supplies

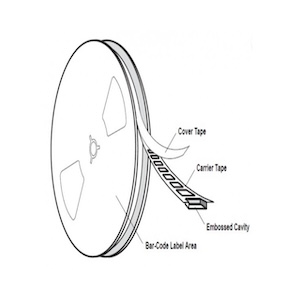

Fig 3: Reel with carrier tape

Fig 4: Reel and packaging tape for the SMD electronic components